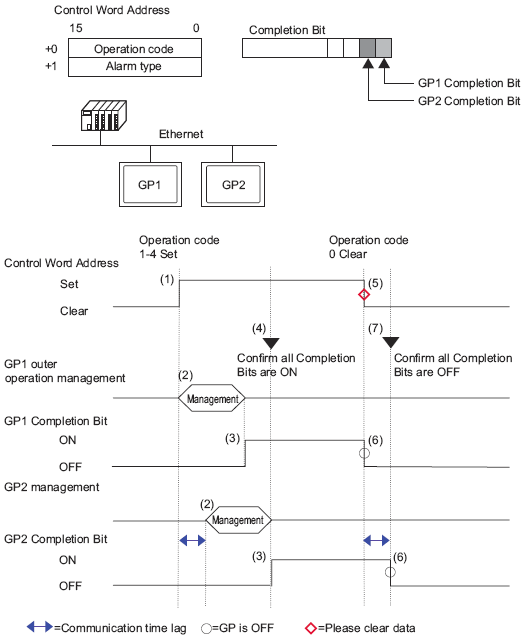

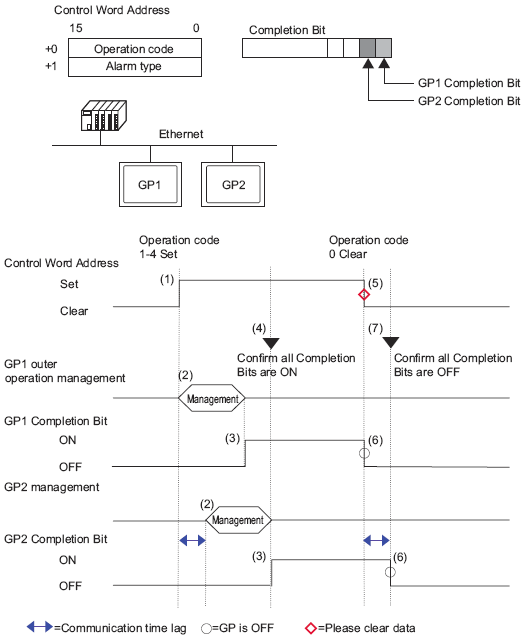

External operations can be performed by multiple display units at one time. However, a time lag will occur due to each display unit's read time, and the order in which the operations are performed and the [Completion Bit] turns ON will differ. Set the operation code after verifying that every [Completion Bit] in each display unit has turned OFF.

Also, when clearing the operation code to "0", ensure that every [Completion Bit] in every display unit has turned ON.

Example)

Using multiple display units (GP1, GP2), set the same address for the [Control Word Address] for external operations, and set separate addresses for the [Completion Bit] of each display unit.

Set the operation code and alarm type in the [Control Word Address] from the PLC.

GP1 and GP2 process orders from the PLC.

When the operations finish, the GP1 and GP2 [Completion Bit] turns ON.

The PLC verifies that each [Completion Bit] in all the display units is now turned ON.

Run the [Control Word Address]'s [Operation Code] "0" (no operation) from the PLC.

When the display unit writes "0" as the [Operation Code], the [Completion Bit] turns OFF.

The PLC verifies that each [Completion Bit] in all the display units are now turned OFF.

![]()

Design the system such that the [Control Address] and [Completion Bit Address] are set to zero at the startup. This is a precaution for when the display unit is turned OFF during operation.

While running operations on multiple display units from the PLC, alarms that are triggered or recovered may not be the same on each display unit.

If you run an external operation to acknowledge all within a block, the acknowledgement order will be [History], [Log], and [Active]. If the same message is registered in both [History] and [Log] when you use real-time printing, the acknowledgement will be printed for both, [History] and [Log], resulting in duplicates.